Add to Cart

Introduction

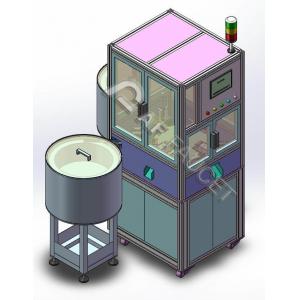

This exclusively designed machine can assemble base, handle, and pins. Automatically leveling and shaping, feeding, assembly, unloading etc. Stable and easy HMI program for operation and control.

1. This assembly line is suitable for φ25, φ35, and φ40 mm ceramic cartridge's base, handle, and pin assembly.

2. Stable running, working up to 20 hours non-stop.

3. Cycle time: 2.5S/Unit 10000 sets / 8 hrs

4. This assembly line is environmentally friendly, green technology.

Assemble Procedures

1# Base Assemble

2# Handle Assemble

3# Vacancy

4# Pin assemble

5# Detection

6# Qualified products unloading station

7# Vacancy

8# Unqualified products unloading station

Key Modules

1. Leveling & Shaping system: it contains a storage plate, base, controller, etc. All 3 parts are separately transported to the pointed location by independently feeding plates.

2 Feeding system: cylinder, mechanical structures, etc. The feeding mechanism transports the parts to the pointed position one by one and gets ready for assembly.

3. Transfer system: it contains a motor, controller, workpiece fixture, photoelectric positioning, and other mechanical parts. After the equipment start working, the Leveling & Shaping system placed all the products in groups and transported them by feeding system to the positioning areas to get assembled.

4. Operation & control system: PLC +Touch screen

Working Environment

Working environment temperature: 0 ≤ 45 ℃;

Humidity: 20 ≤ 90% RH;

Power supply: single-phase 220VAC, 50Hz, 2KVA

Compressed air: 2 kgf/cm, tolerance: ±10%;

Installation Area: 1400mmX1400mmX1900mm

No strong magnetically zone, and no noxious gas in the workshop

We provide customized lines according to the customer’s products, production throughput, and layout plan of the workshop, please contact us for a free consult. Turnkey service is available.